Leading Textile Fogging and Humidification System manufacturer and Supplier in India

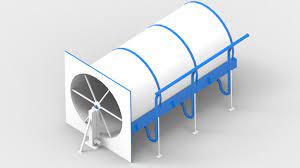

Manufacturer, supplier and Exporters of textile and humidification system for spinning mills, ginning and textile units. Our system helps improves the strength of the fibre by improving the quality. A High Pressure Cold Water Humidification System developed for installation within air conditioning plants. A compact pumping station pumps water via a two stage filter to special nozzles where it nebulizes under high pressure in aerosol mist and is mixed with air by means of turbulence elements.

Humidification plant in textile industry and Spinning Mills

Humidification in textile manufacturing has many benefits that will enhance profitability:

Product weight – preventing moisture loss during a textile’s processing and storage can reduce weight loss from a typical 4% to just 0.5%.

Yarn quality – correct humidification will maintain yarn strength and elasticity, producing a better quality product with higher margins. Wastage is also reduced through a reduction in shedding.

Static control – Static can cause reduced productivity and product quality due to lint and fly attraction, machine jams and employee discomfort or even accidents. Higher humidity naturally dissipates static charges alleviating these problems.

Weaving efficiency – optimal humidification reduces yarn breakages in weaving, reducing machine downtime as well as loom stop marks and weavers knots in the finished product.

Employee comfort – humidifiers can deliver between 5-12°C of evaporative cooling to a textile production facility, while suppressing dust, fly and lint. This creates a healthier and more productive atmosphere for employees.

Our products

Benifts of Textiles Fogging System

- Weight gain in ginned cotton

- Low Installation Cost

- Custom-designed system

FAQ

A High Pressure Cold Water Humidification System developed for installation within air conditioning plants.

A compact pumping station pumps water via a two stage filter to special nozzles where it nebulizes under high pressure in aerosol mist and is mixed with air by means of turbulence elements.

Due to this nebulization and intensive air mixing, the greater part of the water evaporates.

A droplet eliminator at the humidifier outlet ensures that no water is carried over and subsequent ductwork remains dry.

- Efficient high-pressure humidification

- Hygienic and energy-saving

- High degree of humidification & evaporation

- Hygenically Safe (VDI 6022)

- No water tank or storage

- Small amounts of spray water used

- Minimum pump power requirement

- Maintenance & service friendly

- Textile (e.g. weaving, twisting, etc.)

- Nonwovens

- Production of hygiene products

- Food industry

- Energy-saving

- High production throughput

- Enables compliance to hygiene norms

humidification plant in textile industry | humidification plant for spinning mill | humidification system for textile industry | humidification equipment | humidification chamber | textile humidification | humidification plant in textile industry | artificial humidification in factories | humidification plant in textile industry textile humidification plant | humidification and ventilation management in textile industry | textile humidification system | humidification in textile industry | humidity in textile industry | textile humidification plant manufacturers in Coimbatore

conatct Us

- Coimbatore

- contact@ekasynergy.com

- ekasynergygroup@gmail.com

- +91 94448 77783